Flavoring Extract Hazardous Waste: Disposal, SDS Review & Compliance

December 23, 2025

Learn how flavoring extracts can become regulated waste when they meet certain conditions—and how to manage them when they do. Q&As in this entry include:

- How can food-grade flavoring extracts become regulated waste?

- Can you recycle bulk quantities of expired flavoring extracts?

- What should be included in a compliance checklist for handling and disposing of large amounts of food-grade flavoring extract waste?

- What is a hazardous waste determination?

- What is an SDS review?

- What Is a Safety Data Sheet (SDS)?

- What is flashpoint testing?

- What is a good example of an SDS review for a flavoring extract hazardous waste?

- Is there an easy-to-use table for classifying expired or unusable flavoring extracts and other liquids for disposal?

- Where can you get help and advice about flavoring extract hazardous waste?

1. How can food-grade flavoring extracts become regulated waste?

A food-grade extract might be deemed a regulated waste if it expires and is no longer usable for consumption, if it’s off-spec or mislabeled and can’t be used, or if it’s contaminated during manufacturing or transport.

This is because many flavoring extracts contain carriers or solvents that are composed of alcohols or other volatile organic compounds (VOCs) that can be flammable, toxic, reactive, or otherwise harmful to the environment.

For example, vanilla extract is a flammable flavoring because it typically contains 35 percent and upwards of ethanol.

Small “household” quantities of flavoring extract waste aren’t an issue. But industrial- or commercial-sized volumes of extract waste can trigger thresholds for hazardous waste generation, making a business subject to RCRA accumulation, storage, labeling, and disposal requirements—along with any number of state and local regulations.

Also be advised, the DOT classifies bulk quantities of extracts as hazmat for transportation.

2. Can you recycle bulk quantities of expired flavoring extracts?

Not really.

Recycling bulk quantities of expired flavoring extracts is virtually impossible because they typically contain alcohol, oils, and other organic compounds that aren’t suitable for standard recycling (see Q.2). That said:

If the extract is natural, non-toxic, and alcohol-free, industrial composting might be an option. But the compost facility might require lab analysis or SDS (Safety Data Sheet) documentation before accepting it. (See Q.6)

In sum, if you have large bulk quantities of expired or otherwise unusable flavoring extracts that require disposal, you have a hazardous waste disposal challenge on your hands. Get expert advice.

3. What should be included in a compliance checklist for handling and disposing of large amounts of food-grade flavoring extract waste?

Our experts recommend that a compliance checklist contain these eight sections:

Hazard Determination

- Consulting SDSs for each flavoring to determine hazards.

- Identifying all ingredients in the flavoring extract (e.g., ethanol or propylene glycol).

- Checking for hazardous characteristics (i.e., flammability, toxicity, corrosiveness, or reactiveness).

- Performing a hazardous waste determination (per 40 CFR §262.11).

Waste Characterization

- Analyzing the composition and properties of a waste to determine the proper strategies for its handling, treatment, and disposal. I.e., its physical, chemical, and biological characteristics, and whether it’s RCRA ignitable (D001), corrosive (D002), reactive (D003), or toxic (D004-D043).

Labeling & Storage

- Using proper containers (e.g., non-leaking and compatible with contents).

- Labeling containers clearly with a description of contents, the date the accumulation began, and (if applicable) the words “Hazardous Waste.”

- Keeping containers closed except when adding waste.

- Storing in designated, ventilated areas away from heat sources.

Accumulation & Quantity Tracking

- Tracking the amount of hazardous waste generated per month and following generator-specific rules for accumulation time limits and reporting, bearing in mind that the EPA classifies hazardous waste generators into three categories: Large Quantity Generators (LQGs), Small Quantity Generators (SQGs), and Very Small Quantity Generators (VSQGs). Specifically:

- LQGs produce 1,000 kg or more of hazardous waste per month and must follow strict storage, reporting, and training requirements.

- SQGs generate between 100 kg and 1,000 kg per month, facing moderately stringent rules, including contingency planning and waste minimization efforts.

- VSQGs generate less than 100 kg monthly and have the fewest regulatory burdens, though they must still ensure proper hazardous waste management and disposal practices.\

Waste Disposal

- Using a licensed hazardous waste hauler or disposal facility.

- Ensuring proper hazardous waste manifesting.

- Keeping disposal records for at least 3 years.

Employee Training

Personnel should be conversant with hazmat rules concerning:

- Identifying flavoring extract hazardous waste

- Proper handling and labeling of flavoring extract hazardous waste

- Emergency procedures and spill response for flavoring extract hazardous waste

- Keeping records of training sessions and participants

Documentation

Maintaining records for:

- Hazardous waste determinations

- SDSs for each product

- Manifests and disposal receipts

- Inspection logs (e.g., weekly storage area checks)

- Updates to your Hazardous Waste Contingency Plan (if applicable)

Environmental and Safety Compliance

- Conducting periodic audits of waste management practices.

- Checking for state-specific rules (e.g., California DTSC, New York DEC).

- Ensuring compliance with fire code and local sewer authority rules.

4. What is a hazardous waste determination?

A hazardous waste determination is a step-by-step process to assay if a solid material is a regulated hazardous waste. It involves checking if the material is a RCRA listed waste, a RCRA characteristic waste, or (happily) is excluded from regulation.

You can make the determination using “generator knowledge,” which includes information about the process that generated the waste; the chemical or physical properties of the waste; and/or information from suppliers, employees, or SDSs.

Alternatively, you can seek analytical testing by collecting a representative sample of the waste and submitting it to an accredited lab that will use approved test methods to determine its characteristics.

(N.B. Per the EPA, the term “solid material” includes solids, liquids, and contained gases that have been discarded, abandoned, or are recycled in certain ways. That’s not an error: in the world of governmental rulemaking, a liquid is a solid…and don’t argue.)

5. What is an SDS review?

An SDS review involves examining a Safety Data Sheet to understand the hazards, handling requirements, and regulatory information about a chemical or product—in this case a flavoring extract. Specifically, you’re looking for:

- Hazardous ingredients (e.g., alcohol)

- Physical hazards (e.g., flammability, reactivity)

- Health hazards (e.g., toxicity, irritants)

- Flashpoint and other properties relevant to hazardous waste classification

- Disposal recommendations

- Transport classifications (DOT hazard class, UN numbers)

6. What is a Safety Data Sheet (SDS)?

An SDS is a standardized document required by OSHA that provides critical safety information about a chemical or product, including:

- Chemical properties

- Health and physical hazards

- Safe handling and storage

- Spill response and first aid

- Disposal guidelines

7. What is flashpoint testing?

Flashpoint testing is a laboratory procedure used to determine the lowest temperature at which a liquid gives off enough vapor to form a flammable mixture with air near its surface—and ignite briefly when exposed to an ignition source. There are two main methods:

- Closed-cup testing is the most common. The sample (e.g., vanilla extract) is sealed in a cup and slowly heated. The vapor above the liquid is exposed to an ignition source. When it briefly ignites, that’s the flashpoint, which is 610F in the case of vanilla extract.

- Open-cup testing is less rigorous and sounds like something you can safely try at home. Therefore, it’s less commonly used for regulatory purposes. The sample is heated in an open container, and a flame is passed over the surface.

8. What is a good example of an SDS review for a flavoring extract hazardous waste?

To answer that question, let’s consider something as benign sounding as vanilla extract. (Would you even think that vanilla extract had an SDS attached to it?) Looking at it section-by-section:

- Section 2 (Hazards)—tells you that it’s a flammable liquid (Category 2).

- Section 3 (Composition)—tells you that it’s 35 percent alcohol.

- Section 5 (Firefighting)—tells you that its vapors might ignite, and if that happens, use foam or CO2 to put out the fire.

- Section 9 (Flashpoint)—tells you that if the ambient temperature is above 610F, it will ignite if placed near an ignition source (see Q.7).

- Section 13 (Disposal)—reminds you to dispose of it in accordance with federal/state/local laws (as if you needed to be told that).

- Section 14 (Transport)—tells you that it’s a UN1170, ethanol solution, flammable liquid, Class 3.

The upshot in plain vanilla: you have a hazardous waste on your hands for ignitability (D001) that requires flammable storage and hazardous waste management. Get help & advice here.

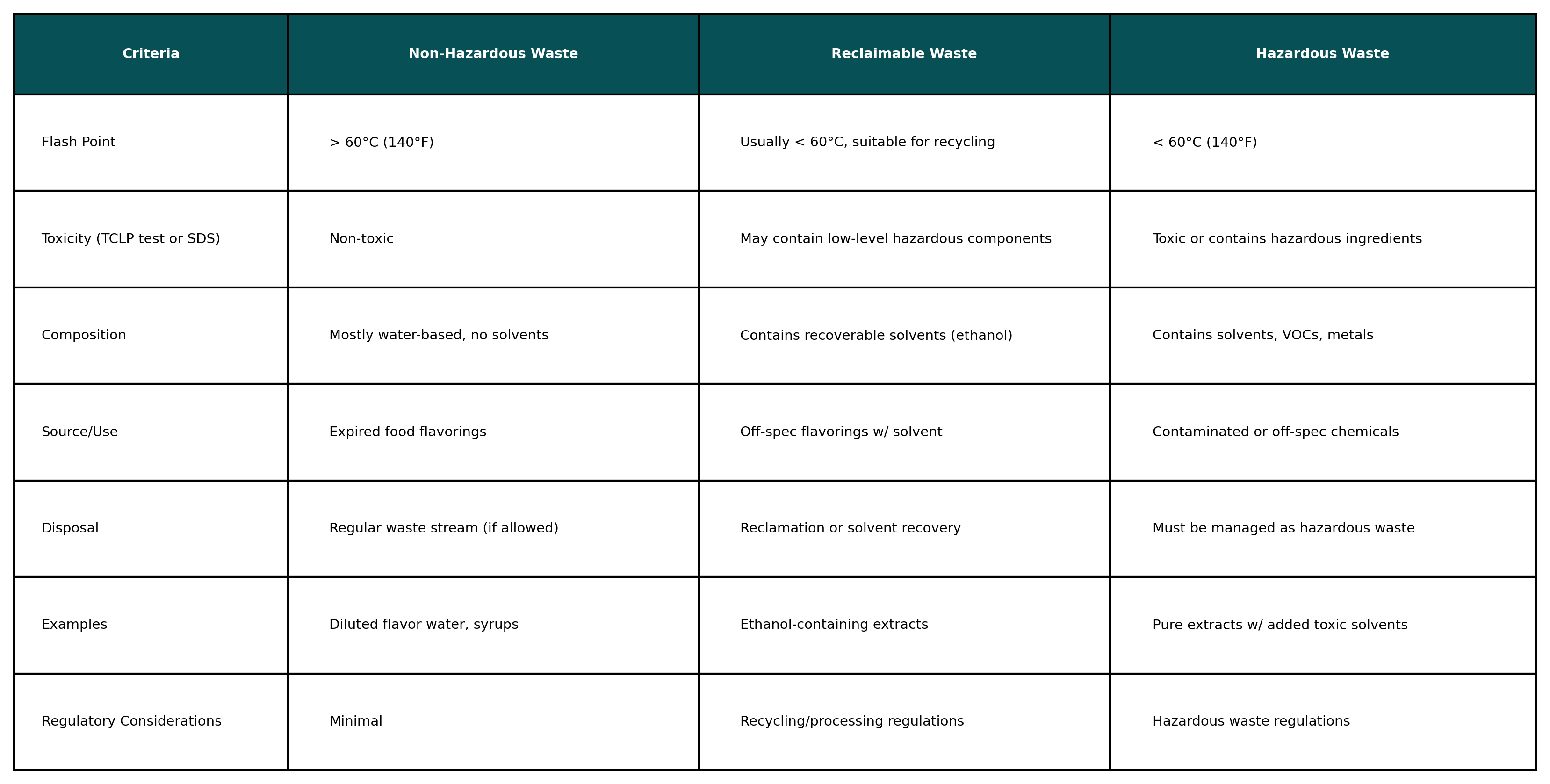

9. Is there an easy-to-use table for classifying expired or unusable flavoring extracts and other liquids for disposal?

We like this one:

10. Where can you get help and advice about flavoring extract hazardous waste?

Expired food flavorings, especially those containing alcohols, solvents, or reactive compounds, can be classified as hazardous waste, requiring careful disposal to comply with environmental regulations. Hazardous Waste Experts specializes in helping food and beverage manufacturers safely manage these materials.

Accurate waste profiling is key. It identifies hazardous components upfront, reducing unnecessary disposal costs and avoiding costly shipping violations due to misclassified materials.

Our team ensures each waste stream is correctly labeled and manifested for safe transport. We also provide straightforward safety and storage tips—like segregating incompatible chemicals, using sealed containers, and keeping flavorings in cool, ventilated areas—that lower risks without expensive facility upgrades.

With our guidance, your company can stay compliant, minimize liability, and handle waste with confidence.

Whether you’re dealing with small batches or large volumes of expired flavorings, we make hazardous waste disposal simple, affordable, and safe. Let us help you turn regulatory challenges into streamlined solutions.

Contact us today. Or call us at our new number: 425.414.3485.

And thank you for reading our blog!